SINGLE-USE CONTAINERS: WHAT DOES THE LAW SAY?

Article 28 of the EGalim law mandates the elimination of plastic food containers used for cooking, reheating, and serving in school and university catering services, as well as childcare facilities for children under six years old, by January 1, 2025.

Matfer Bourgeat introduces SESAME: a patented (2 patents), innovative stainless steel tray and lid system that is easily sealable, fully reusable, and designed to replace single-use containers in kitchens, ensuring food safety and compliance with all regulatory requirements.

DESIGNED AND DEVELOPED IN FRANCE

Months of field observation to ensure every constraint in collective catering operations was considered.

Manufactured 100% in France (Rhône-Alpes) using stainless steel that is processed, recycled, and revalorized in Europe.

ADAPTABLE TO ALL KITCHEN SIZES

SESAME fits all types of kitchen environments — from 1 to 100,000 meals/day — and all levels of automation in packing or washing lines.

DESIGNED TO ELIMINATE MUSCULOSKELETAL DISORDERS (MSDs)

No effort is needed to open or close the tray.

Thanks to its partial vacuum-sealing system (patented), the tray seals in seconds with perfect airtightness — manually or automatically.

The easy-grip valve allows effortless opening, with no risk of splashing hot liquids.

GUARANTEES FOOD SAFETY

Its silicone valve ensures food safety. When the valve is opened, the characteristic “pschitt” sound confirms the container’s tamper-proof integrity.

EASY TO STACK AND UNSTACK

The tray’s shape allows compact stacking (30% space-saving compared to a standard tray) and smooth manual or automatic unstacking with no jamming.

FULLY TRACEABLE

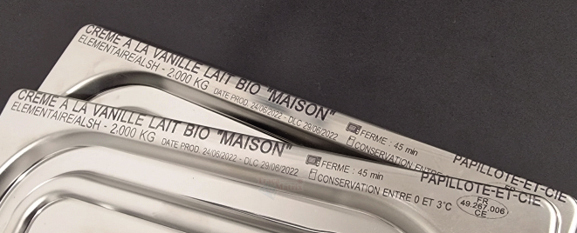

Each lid and tray features a unique identification code (patented) engraved directly into the stainless steel (DATAMATRIX).

This code enables precise tracking and optimized inventory management through database integration.

EASILY IDENTIFIABLE

Color-coded valves provide quick and easy content identification for operators.

Regulatory markings (use-by date, approval number, etc.) can be inkjet printed directly on the lid during the packaging process.

A RANGE TO SUIT EVERY NEED

Available in GN1/2, GN1/3, GN1/4, and GN1/6 formats with adjustable depths up to 100 mm, and a 0.7 mm thickness — the optimal balance between weight, durability, and mechanical resistance to partial vacuum-sealing.